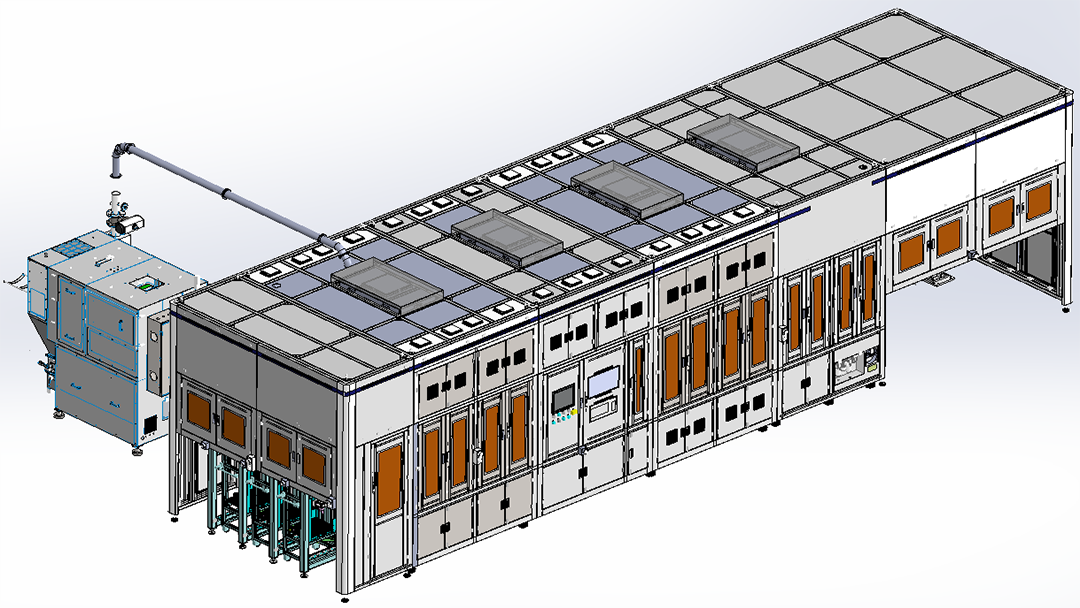

· Product Description

The equipment is mainly used for the laser welding machine of the anode cover plate to weld the cell tab and the anode cover plate together. It has the functions of cell scanning, cell feeding, cell rotation, cell 45° turning, top cover feeding, top cover positive and negative & anti-stay detection, tab position detection, tab cover welding, dust removal after welding & shaping, welding mark detection, welding mark adhesive, adhesive detection, fixture dust removal, and cell unloading.

The final optimal rate of equipment: ≥99.8%(except bad incoming materials);

Failure rate :≤2%; CMK:≥1.67(welding tension); Equipment capacity :≥16PPM.

Welding requirements: effective melting depth :200-800um, effective melting width :≥2.0mm; Laser welding: two welding marks, divided into :2*13mm, 2*9mm, two welding marks within the spacing 10.5mm; The horizontal distance between the top cover and the aluminum shell is 3mm; Welding tension: ≥100N(horizontal tension); The fault on both sides of the welding imprint is ≤30%, and the welding residual surface is ≥75%.

Defocus detection: defocus control comprehensive accuracy ≤±0.1mm.

Welding quality requirements: welding line burst point - shield welding line starting point position interference, diameter >0.3mm; The missing kill rate was 0%, and the overkill rate was less than 1%. The length and width of the welding wire do not meet the requirements - the length of a single welding wire is 3.5-10mm, the width of a single welding wire is 1.5-4mm, and the defective missing length is >0.3mm; The missing kill rate was 0%, and the overkill rate was less than or equal to 1%. Pole ear cracking detection - Bad length ≥1mm.

CCD detection before welding: detection accuracy ±0.15mm; The missing kill rate was 0%, and the overkill rate was less than 1%.

Adhesive size (length x width, unit mm):47*9mm, material width 47mm; The cutting accuracy of the tape is ± 0.5mm, and the size deviation of the adhesive positioning is ±1mm.

Adhesive CCD detection: detection accuracy ±0.15mm; The missing kill rate was 0%, and the overkill rate was less than 1%