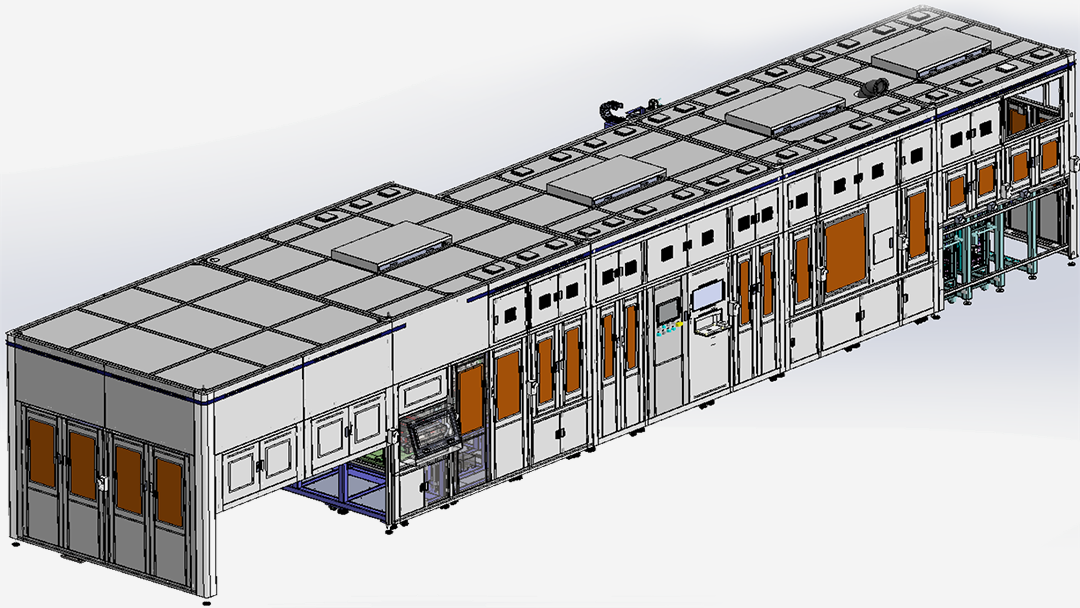

· Product Description

The equipment is suitable for laser welding of CL series prismatic aluminum shell laminated cell tab and cover plate. It mainly includes the following modules: top cover feeding, top positive and negative anti-stay detection, top cover engraving, clear and secret code recognition, cell scanning, cell loading, electrode cover plate welding, welding mark shaping & dust removal, welding mark detection, welding mark paste, welding mark paste detection, large surface dust removal, large surface CCD detection, secondary Hi-pot test, cell unloading, NG cache, etc.

The final optimal rate of equipment :≥99.8%(except bad incoming materials); Single process DT ≤ 2%;

Equipment capacity :≥16PPM;

Laser engraving requirements: with heavy code to anti-stay, a decoding success rate is greater than 99.99%, the engraving grade meets the B level or above, the configuration of a proprietary scanning gun to confirm the engraving effect, the scanning gun has the function of light and dark code recognition.

Laser welding requirements: effective welding area ≥ 75%; Welding tension ≥ 200N(parallel tension), fault less than 30%, effective penetration depth 0.2-0.8mm; Effective melting width :>2.0mm; The comprehensive precision of defocus control is ≤ ±0.1mm, and the laser head jitter is ≤ 0.03mm during welding.

Welding mark dust removal and testing requirements: After welding, oxidation, welding, welding penetration, explosion point, weld length, width, explosion point and other defects are confirmed by CCD detection.

Welding paste & testing requirements: tape size :8*98mm; The cutting length deviation is ± 0.5mm, the tape needs to be replaced quickly, and the replacement time is less than 2min. CCD is used to detect the glue position effect, position, size, and missing paste, etc. The detection accuracy is (according to 5 pixels): ± 0.15mm, the missing kill rate is 0%, and the overkill rate is 1%.

Large surface dust removal and detection requirements: the overall negative pressure dust removal of the battery cell, including the upper and lower surfaces of the cell, wind speed ≥ 25m/s, negative pressure monitoring; The appearance of the two large surfaces was detected, and the detection accuracy of metal foreign bodies >0.2m㎡, black spots and damage, and diaphragm bending (exposing pole pieces) was ± 0.15mm, the missing rate was 0%, and the overkill rate was <1%.

Hi-pot detection: pressure 100-600kgf adjustable, pressure control accuracy ±3%, pulse test mode, test voltage 250V, pressure design 700kgf, pressure accuracy ±3%, test time 200-400ms adjustable, VD1 ≤ 5%, VD2 ≤ 10%(excluding charge and discharge time, charge and discharge time is designed according to ≤ 500ms) The instrument range is adjustable, and the voltage is adjustable from 50-1000V;