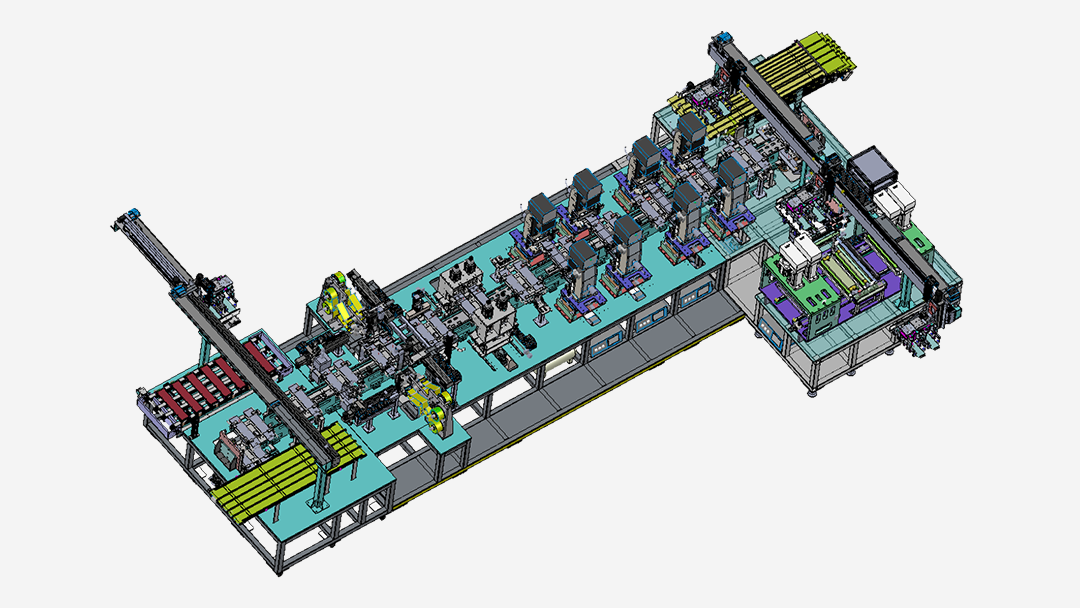

· Product Description

The equipment is mainly used for ultrasonic welding machine to pre-weld the cell and the tab, and the tab is formed into the desired shape (including loading and unloading logistics line, code scanning, Hi-pot detection/thickness measurement, tab folding CCD detection (including the positive and negative most outer tab folding and diaphragm, tab pieces folding), ultrasonic pre-welding (flat tooth welding process), tab cutting, welding printing, post-welding CCD detection and so on.

The final optimal rate of equipment :≥99.5%(except bad incoming materials); Failure rate ≤2%; CMK:≥1.67(welding tension); Equipment capacity: ≥ 16PPM;

Hi-pot test requirements: pressure design 5t, pressure accuracy ±3%, flatness ≤±0.04mm, parallelism ≤±0.08mm, pulse type, test time 200-400ms adjustable, voltage 50-1000V adjustable, VD1≤5%, VD2≤10%, equipped with calibration standard resistance (provided by customers);

Thickness measurement requirements: Pressure adjustable from 100-600 kgf, pressure accuracy of ± 3%, repeatability accuracy of ± 0.015mm, calibration block accuracy of ± 0.05mm, single-pole configuration with 2 detectors, press plate flatness ≤ ± 0.04mm, upper and lower press plate parallelism ≤ ± 0.08mm.

Welding mark requirements: anode welding size: single welding 6*30m㎡, cathode welding size: single printing 6*40m㎡; A single tab is welded 2EA each time, and the welding mark is 5mm, a total of 2 times 4EA; Welding tension requirements ≥50N; Residue >50%, the effective area of the first three layers of peeling residue welding impression ≥90%, the middle layer ≥ 10%;

Adhesive size (length x width, unit mm): Anode upper position 18±5*68mm, Anode lower position 24 ±5*68mm, Cathode upper position 16±5*98mm, , Cathode lower position 16±5*98mm; CCD was used to detect the effect, position, size and missing patch of the upper and lower adhesive positions, and the detection accuracy (according to 5 pixels) was ±0.15m, the missing kill rate was 0%, and the overkill rate was less than 1%.

Tab cutting knife :1. Material super hard alloy, life > 300,000 times, tab section burr after cutting ≤50um, no wire drawing; After cutting: positive tab 20±1mm; Negative tab 13±1mm;

CCD detection :1.CCD camera 5 million pixels, 2. Tab cutting detection accuracy ±0.5m, 3. Tab alignment detection accuracy ±0.1mm, 4. Folding/cutting detection miss rate 0%, overkill rate ≤1%; 5. Post-welding CCD detection: welding crack (welding crack length ≥ 1mm), welding size, welding position, poor welding, etc., miss rate 0%, overkill rate ≤1%;

Dust removal requirements :1. Sealed dust removal, end wind speed ≥25m/s;2. Real-time monitoring of negative pressure wind pressure, alarm over the lower limit (dust removal air volume, position adjustable)