Innovation

Adhering to the concept of "innovation and leadership", the company has a research institute and a number of product R&D and design centers. The research Institute is responsible for the research and innovation of core devices, key processes and intelligent control technology. The product R&D and design center focuses on the research and development and design of professional process equipment in the industry and provides overall solutions for customers. The company's annual research and development investment accounts for about 10% of the total revenue, and has obtained more than 800 authorized patents.

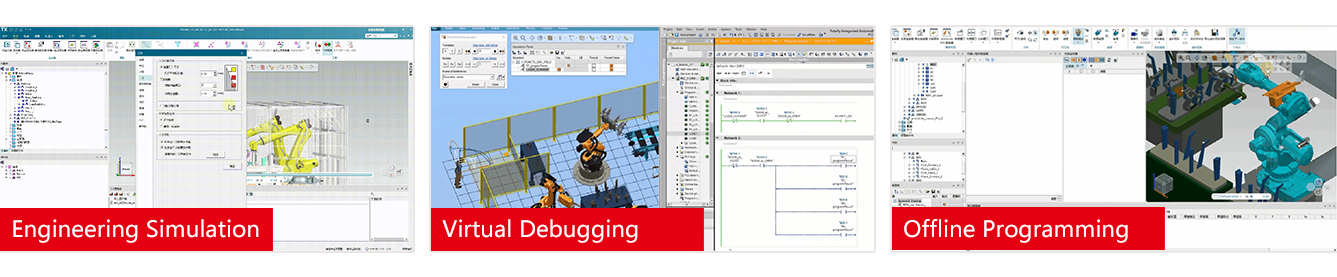

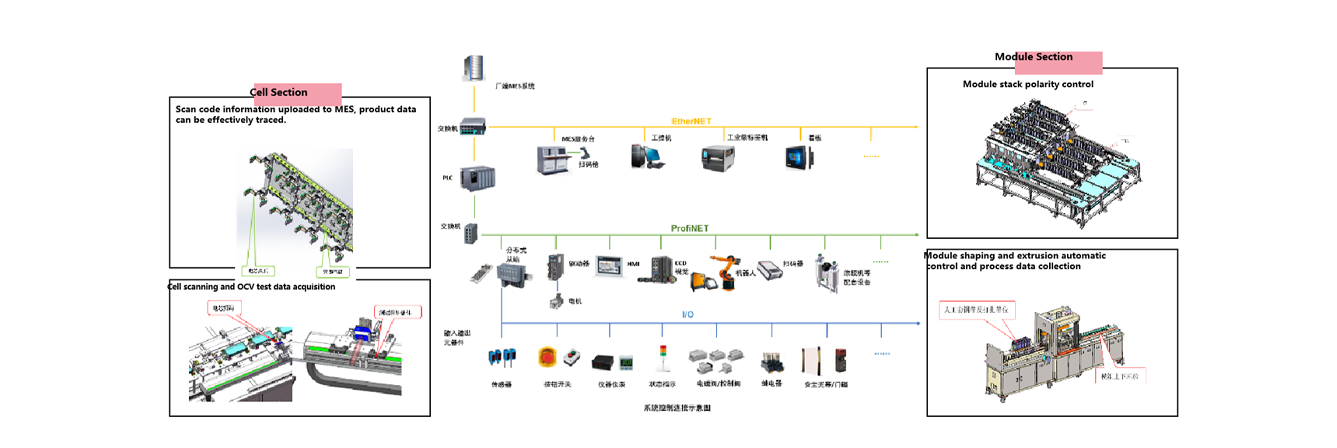

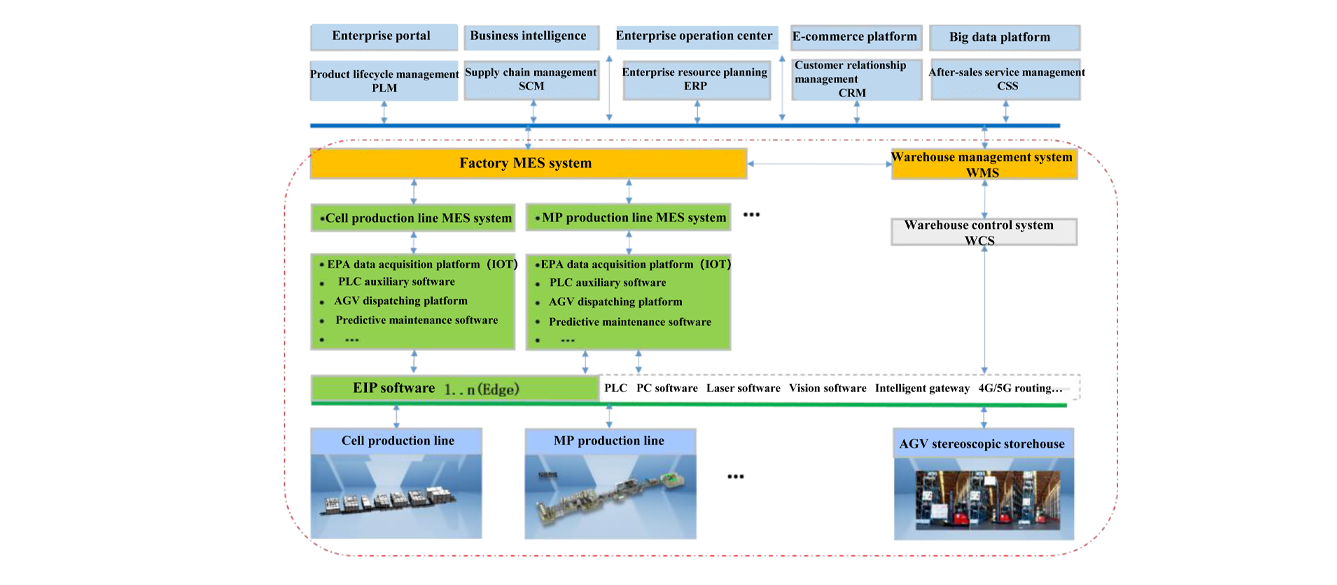

The company provides customers with digital simulation, virtual smart factory simulation plant construction, independent development of smart factory MES system, reduce labor costs, shorten the delivery cycle, predict production line construction problems in advance, greatly improve delivery efficiency and mass production speed. The company cooperates with a number of universities, research institutions, and battery enterprises to jointly develop new battery process manufacturing technologies, including process research, energy conservation research, and heterosexual material processing.