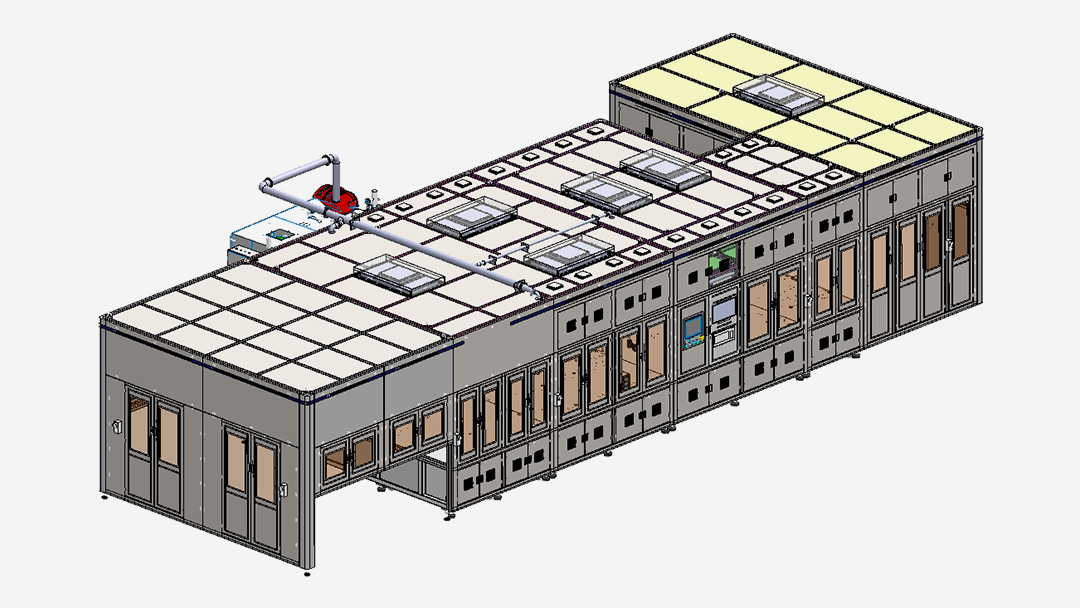

· Product Description

This equipment is suitable for CL series prismatic aluminum shell laminated cell pre-welding into the shell, mainly including the following modules: My1ar after pole group cell loading, cell code scanning, cell dust removal, shell loading, shell weld edge detection, shell dust removal, cell into the shell, cell press assembly, weld detection, negative cover plate pre-welding, post-welding detection, cell unloading, etc.

◆The final optimal rate of equipment: ≥99.85%(exclusion of bad incoming materials); Failure rate ≤2%; CPK: ≥1.67; Equipment capacity ≥16PPM;

◆Inserting shell requirements: shell inserting pressure ≤10kgf, the range can be set, online detection, beyond the range judged as NG, after the completion of the shell, aluminum shell end face and negative cap end face distance 1-5mm adjustable; The position of the shell mouth is equipped with a guide film to avoid friction between the pole group and the shell positioning fixture and the shell mouth. The design of the shell mouth guide structure: the 4 R angles of the inlet shell mouth guide mechanism shall completely cover the 4 R angles of the aluminum shell mouth to ensure that the pole group and Mylar film are not scratched during the inserting shell;

◆Press-assembly pre-welding requirements: real-time monitoring of press-assembly pressure, pressure range 50-1000N, the range can be set, 3D line scan camera is used to detect the steps and gaps after press-assembly, step ≤0.25mm, gap between cover plate and shell ≤0.06mm(detection position: each press-assembly pre-welding spot +R Angle position, R Angle position adopts straight line detection)

◆CCD detection requirements after welding :CCD detection accuracy ±0.15mm, detection requirements: miss kill rate 0%, over kill rate ≤1%, need to add the picture storage function, save the original picture and processed pictures include OK and NG pictures), OK picture storage time ≥1 month, NG picture storage time ≥6 months;

◆Pole group incoming dust removal requirements: dust removal speed of the unit 25m/s, wind speed negative pressure monitoring, less than the required value stop to alarm;

◆Pre-welding dust removal requirements: dust removal mechanism port wind speed ≥15m/s, wind speed monitoring, less than the required value will stop to alarm, dust removal wind speed, position adjustable;

◆Shell dust removal requirements: dust removal mechanism port wind speed ≥25m/s, wind speed negative pressure monitoring, less than the required value will stop to alarm;

◆Laser brand :IPG1500W fiber laser;