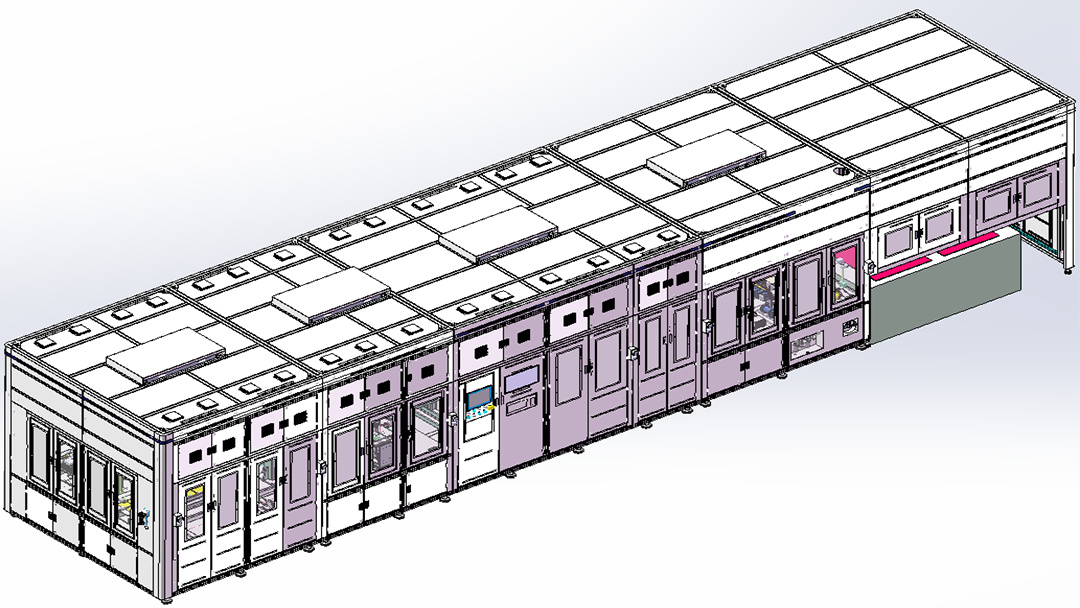

· Product Description

The equipment is mainly used for the CL series prismatic aluminum shell laminated cell package My1ar equipment. Functions include: cell scanning, cell feeding, cathode tab bending, side plate feeding, Mylar feeding, side plate & My1ar hot melt, anode end plate feeding, anode end plate installation, bottom My1ar hot melt, film turning, top My1ar hot melt, side hot melt, side adhesive, hot melt CCD detection, adhesive detection, cell rotation, NG cache, cell unloading.

◆The final optimal rate of equipment: ≥99.5%(except bad incoming materials); Failure rate :≤2%; CMK: ≥1.67(welding tension); Equipment capacity :≥16PPM;

◆Hot melting requirements: hot melting point position accuracy ≤±0.3mm; Heating head temperature adjustable range: room temperature to 300℃; Heating time :1-3s, time is adjustable; Hot melt

pressure :0.5±0.1Mpa, adjustable; Clear and firm welding impression, no virtual welding, over-melting, wire drawing and other abnormalities, a single hot melting point horizontal damage tension ≥10N, effective hot melt area ≥60%; The hot melt head adopts a split type design, which cannot be made into a split type, and two hot melting points can be controlled separately. Hot melt head fillet processing, adjustable position, each group of heating head with temperature control, and temperature detection feedback (internal controller monitoring), more than ±3℃ temperature deviation between the two (configurable) need to alarm feedback, more than 10℃ temperature difference (configurable) alarm stop, the number of hot melt controller ≥1;

◆Gluing requirements: There are 7 gluing lines on the long side. When the side Mylar is wrapped, the side panel should be in the innermost part; The large side of the cell is kept tight during hot melting and gluing. Single tape changing time: ≤2min; Cutter life ≥ 500,000 times, the device automatically statistics the number of times of use, with the tool cleaning, replacement reminder function, when the glue mechanism is placed horizontally, the counterweight should be configured to prevent the tape from bouncing and wrinkling;

◆Hot melt CCD detection :CCD camera 5 million pixels, with material detection function; The position size of Mylar film after hot melting is detected by CCD, and the detection accuracy is ≤±0.15mm; The area, quantity and position of the hot melting point are tested, including 16 points on the upper and lower surfaces. The test requirements are as follows: leakage rate 0%, overkill rate ≤1%; Increase the protection plate around the CCD, control the divergence of light source dazzling CCD camera increase the protection cover, such as the CCD camera lens upward, increase the lens protection camera.