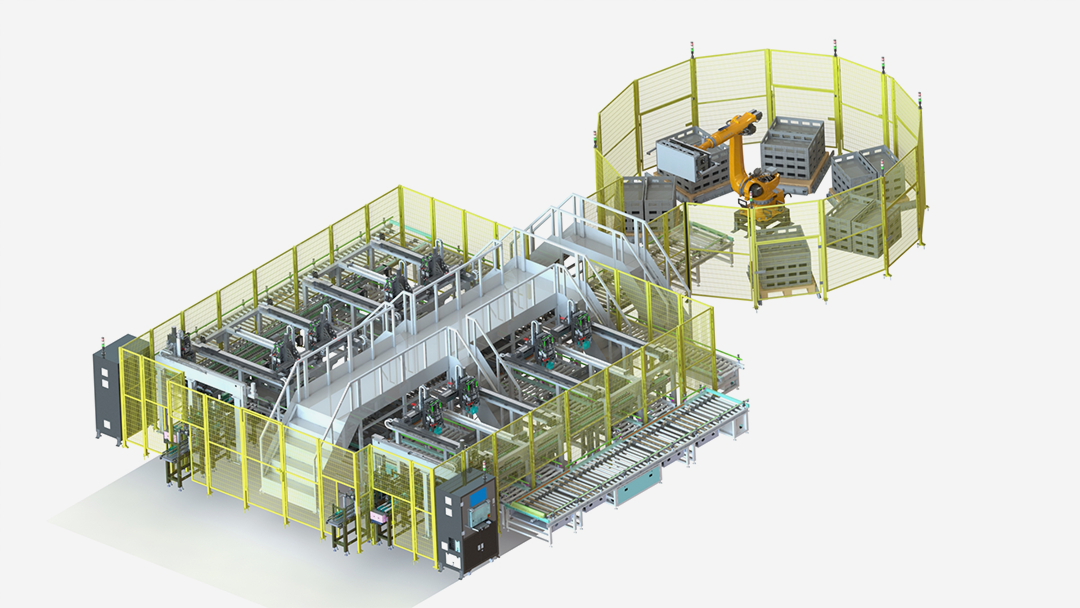

· Product Description

Functions:

This equipment is suitable for sorting open circuit voltage, AC internal resistance, and capacity of pouch cell. It has a QR code scanning function and can read data from various OCV databases provided by MES for data sorting. The classified data supports local storage and uploading to MES servers, as well as manual loading and unloading functions, automatically picking out NG products. Good batteries are divided into multiple levels, and bad products are classified into 1 category (scanning error, high capacity, low capacity, low voltage, large internal resistance deviation, etc.). Good battery cells are assembled in different trays according to the levels, and NG products are cached in NG conveyors. The parameters of each level can be set by Party A in the scheduling system based on the data on MES, and the parameter category can be selected, then the equipment operates automatically.

Parameters

● Final equipment yield rate:>99.9%(defective incoming materials excluded): fault rate: DT≤1%; CPK>1.67;

● Production capacity:1PPM~30PPM; Efficiency can be customized;

● Voltage range: 0-5V;

● Voltage test accuracy:±(0.0035%set+0.0005%FS);

● Voltage display resolution: 2uV;

● IMP range: 0-3000Ω;

● IMP test accuracy:±(0.5%rdg+10dgt);

● IMP resolution:0.1uΩ;

● Unloading and stacking: ABB or KUKA six axis robots are used to stack battery trays of different levels onto pallets, and the subsequent unloading is carried out by manually controlled forklifts or AGVs;

● OCV test: The test adopts an Agilent 34461A voltmeter, and HIOKI BT3562 for the IMP test.