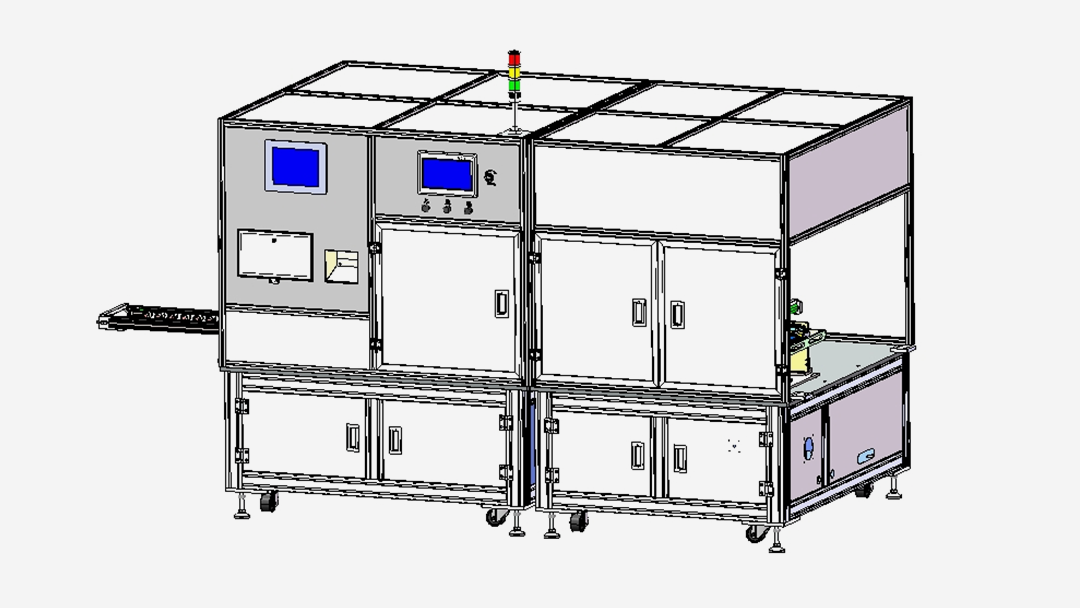

· Product Description

Functions:

This equipment is designed to automate the process of applying protective film (Mylar) on pouch lithium-ion batteries. Integrating mechanical and electrical systems, it features robotic arms for automatic material handling, film preparation, wrapping, and unloading onto a conveyor belt, with the wrapped batteries being sent out via a conveyor.

Equipment parameters:

● Equipment dimension(L*W*H): 3500*2000*2500;

● Weight(ton): 2T;

● All grippers feature a flexible collision-proof design and are equipped with power-off and air-cut protection functions;

● Driven by servo motors with adjustable stroke;

● With CCD detection function;

● Clear identification of NG cache, supporting manual non-stop retrieval of NG materials while ensuring personnel safety;

● The contact area with the battery cell is made of non-metallic materials;

● Connected with the MES system, the process data report can be exported as a detailed report based on production time, shift, battery QR code, and other conditions. At the same time, charts can be generated and saved locally in Excel format;

● Equipment fault rate: ≤2%;

● Yield rate:≥99.5%.