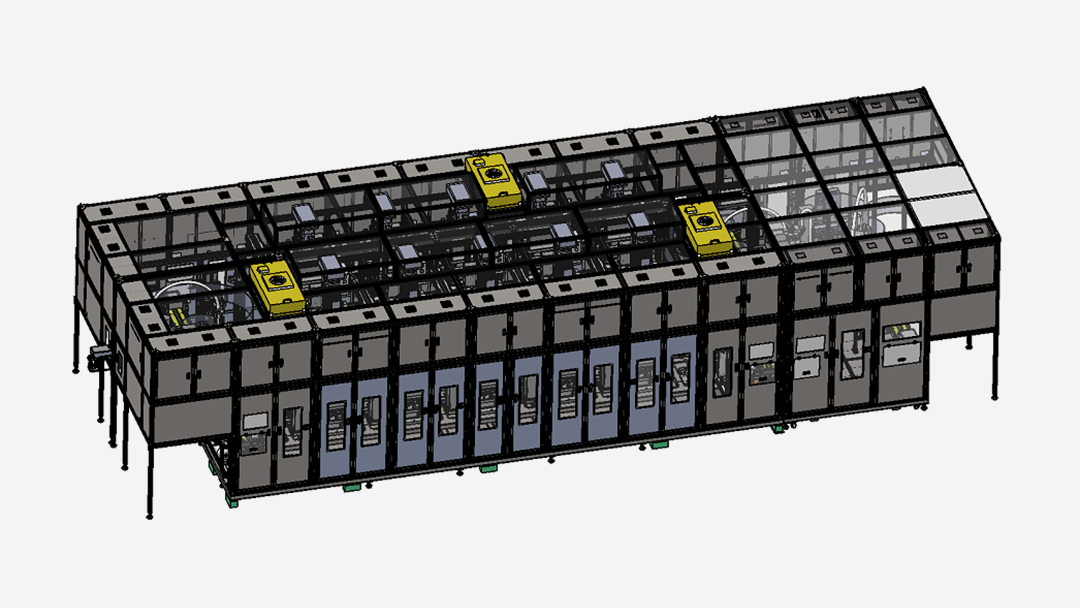

· Product Description

Functions:

The equipment is mainly used for the hot pressing testing process of pouch cells. It performs hot pressing shaping and Hi-pot testing on the battery cells after winding/stacking. Its functions mainly include automatic loading, hot pressing shaping, Hi pot testing, automatic unloading, and information tracing.

Equipment parameters:

● Equipment dimension(L*W*H): 13000*4300*3500;

● Weight(ton): 54T;

● The pressing plate adopts the avoidance design. To prevent indentation at the avoidance position, a hot pressing paper device is used to cover the pressing plate to reduce the indentation;

● Adopting special coating treatment for hot pressing plates + lifting mechanism,preventing the cell from sticking on the top hot pressing plates;

● Parallelism of the upper and lower hot pressing plates: 0.05mm;

● Temperature speed of the hot pressing plates: from ambient temperature to 120℃,accuracy:±5℃;

● Temperature sensor detects the hot pressing temperature during the process. The temperature is controllable;

● Pressure range:10T adjustable. When it is below 5000kgf,the precision is ±100kgf;When it is between 5000kgf and 10000kgf,the precision is ±150kgf. It supports staged adjustment of the hot pressing speed;

● Integrated with short circuit testing system;

● Testing voltage:DC voltage range: 0~500V adjustable;

● Testing time: 190S;

● Testing resistance: Maximum displayed resistance value >9999MΩ;

● Hi-pot testing plate should be activated only when the cells are pressed tightly to prevent misalignment of outer electrodes;

● Equipment fault rate:≤2%,yield rate:≥99.5%.