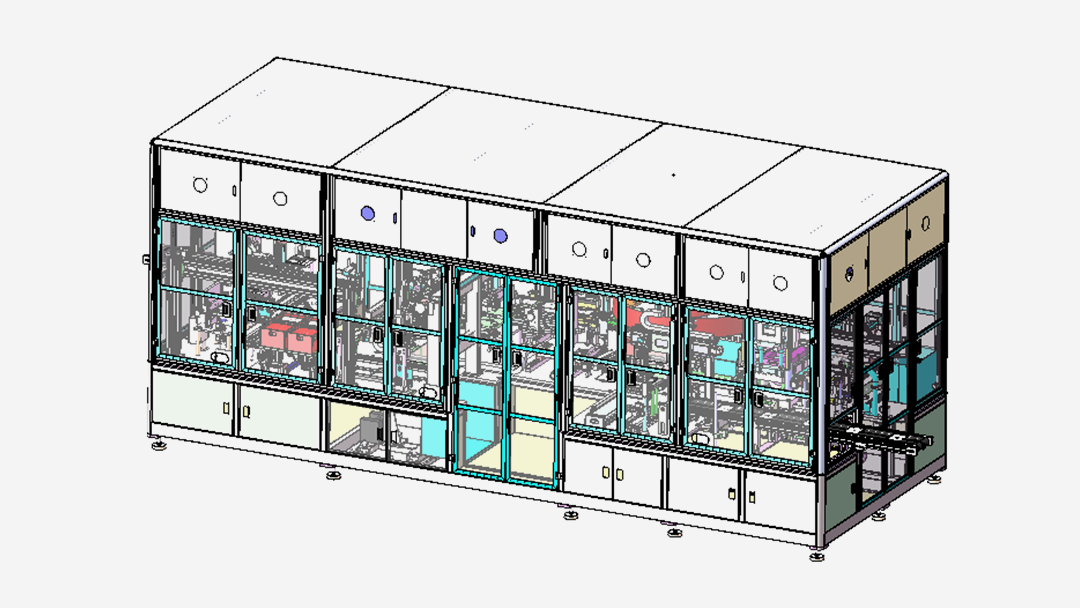

· Product Description

Functions:

This equipment is suitable for the following functions in the production of soft pack lithium batteries: automatic forming of aluminum-plastic film, double cutting of the aluminum-plastic film top, automatic shell loading, CCD positioning/detection, NG cell exclusion, servo top sealing, corner sealing, servo side sealing, high voltage impact of tabs, negative tab-to-shell HV pulse Test, cutting of side edge, code spraying, scanning, CCD detection (detecting tape exposure), sorting of various NG products, single cell unloading pulling, etc.

Equipment parameters:

● Equipment dimension(L*W*H):7500*2600*2400mm;

● Weight(ton): 8T;

● Aluminum plastic film correction:Accuracy:±0.2mm;

● Drawing depth:1.2-6.0mm, accuracy±0.1mm;

● Aluminum plastic film folding line: Accuracy:±0.1mm;

● Cell-into-shell accuracy: CCD photography accuracy: ±0.1mm, cell-into-shell accuracy: ±0.15mm;

● Sealing:Hard sealing. Steel seal heads or other materials with excellent thermal conductivity and thermally-induced deformation properties (seal head material is H62);

● Cell height after sealing: ±0.2mm( Aluminum plastic film misalignment after sealing≤0.5mm);

● Top seal pressure:80Kgf-350Kgf. Side seal pressure: 80Kgf-350Kgf. Real-time online feedback and warning system for top and side sealing pressure. (Driven by servo motors with an adjustment precision of 1Kgf.);

● Sealing temperature:150℃-250℃. Temperature control accuracy:±3℃(Adjustment accuracy:1℃. Tested temperature: ±3℃);

● Cutter lifetime:≥1000,000 times,no obvious burrs or fibers at the aluminum-plastic film rupture;

● Yield rate:≥99%;Efficiency:≥95%.