· Product Description

Functions:

This equipment is used for precision cutting, edge folding and tape sticking, with bladder cutting option. It has the functions of battery loading with a conveyor belt, loading scanning and weighing, battery loading positioning and shaping, pre edge cutting of the bladder, side precision cutting, folding edge shaping, unloading scanning and weighing, NG product automatic sorting, stacking incoming materials on empty vacuum-formed trays, automatic battery feeding into vacuum-formed trays, as well as stacking and unloading of full vacuum-formed trays;

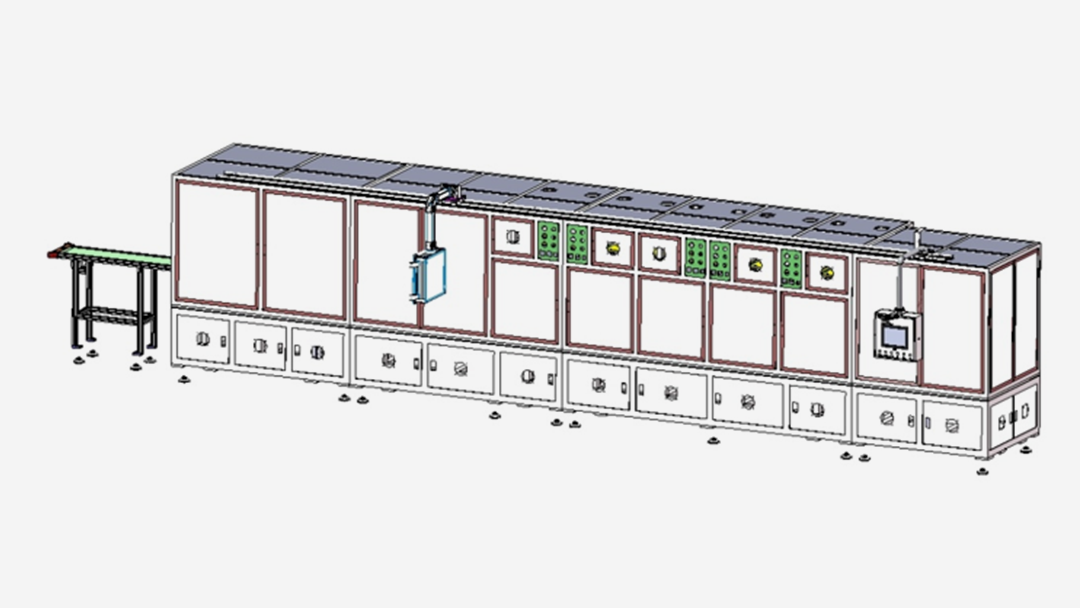

Equipment parameters:

● Equipment dimension(L*W*H): 8000*1500*2500;

● Weight(ton): 7.4T;

● The integrated tape sticking machine for cutting, folding, ironing adopts a step-by-step handling method;

● The width of the folded edge left after cutting is 8-10mm, and there are no defects like curled edges, obvious burrs, wire drawing, bending, continuous cutting, and cutting beyond the specified border, etc.;

● Adopting a double folding method. After folding, the height of the folded edge cannot exceed the surface height of the battery cell;

● When folding, be careful to prevent damage to the folded edge and the battery body, such as scratches, dents, collisions, etc.;

● The accuracy of the folded edge width should be ≤ 0.5mm, and the folded edge plane should be flat after folding. There should be no defects such as wavy edges, curled edges, or uneven height of folded edges (slanted edges);

● Ironing temperature: 100~180℃, adjustable;

● After the tape is applied, the relative position accuracy between the edge of the tape and the side or bottom edge of the battery should be ≤ 0.5mm. The applied tape should not have any defects such as bubbles or warped edges;

● Equipment fault rate:≤2%;

● Yield rate:≥99.5%.

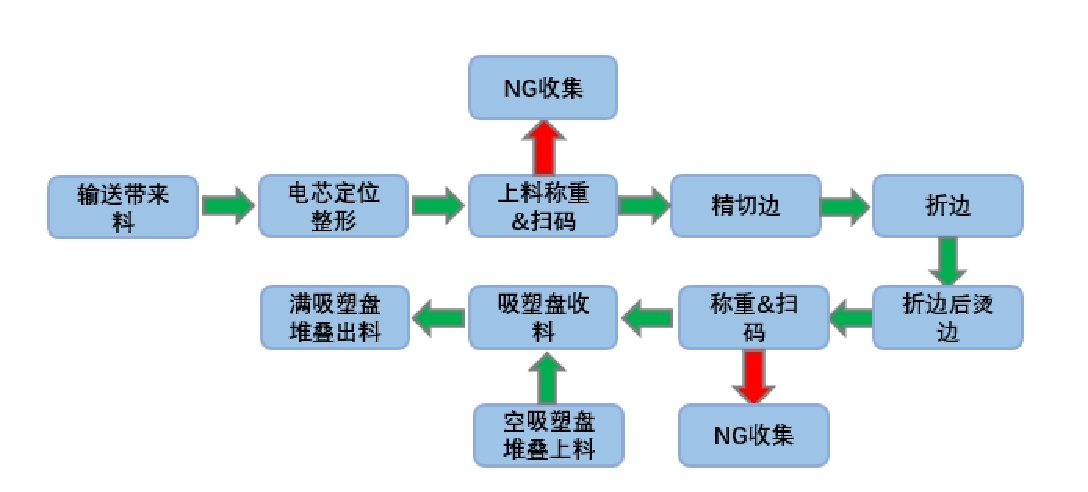

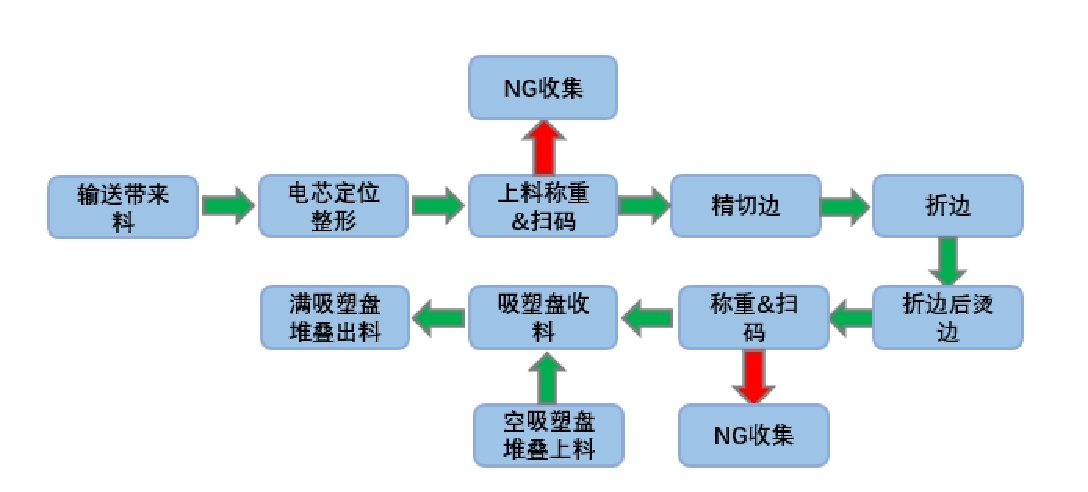

Motion process: