-

Home

-

About Us

-

Global

-

Products

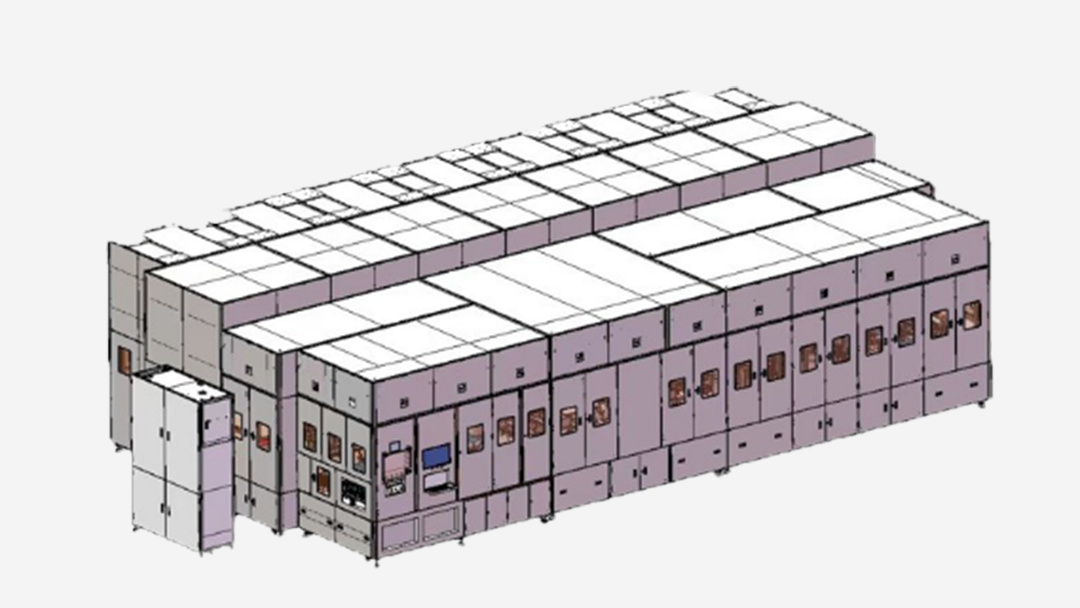

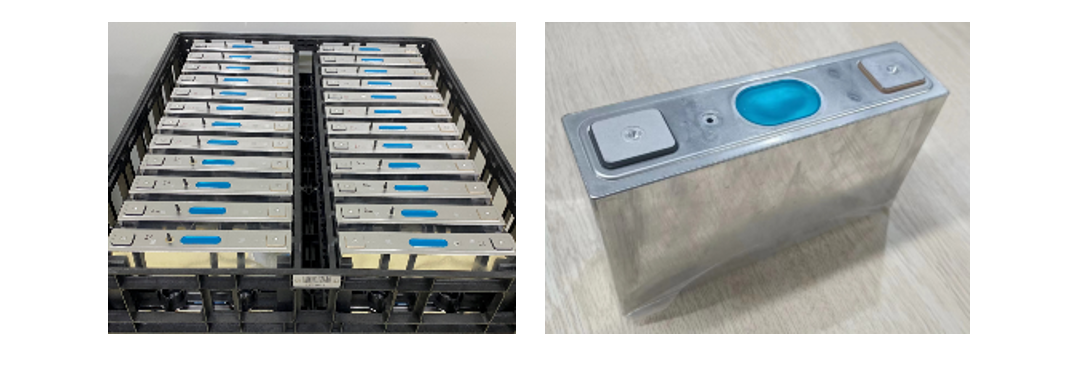

- Power/energy storage battery equipment solutions

- Square battery process solution

- Cylinder battery process solution

- Pouch Cell Production Process Solutions

- Blade Battery Process Solutions

- Module and PACK, CTP assembly line

- Consumer Battery Production Process Solution

- Battery Structural Component Manufacturing Process Solution

-

Innovation

-

News

-

Job

-

Contact